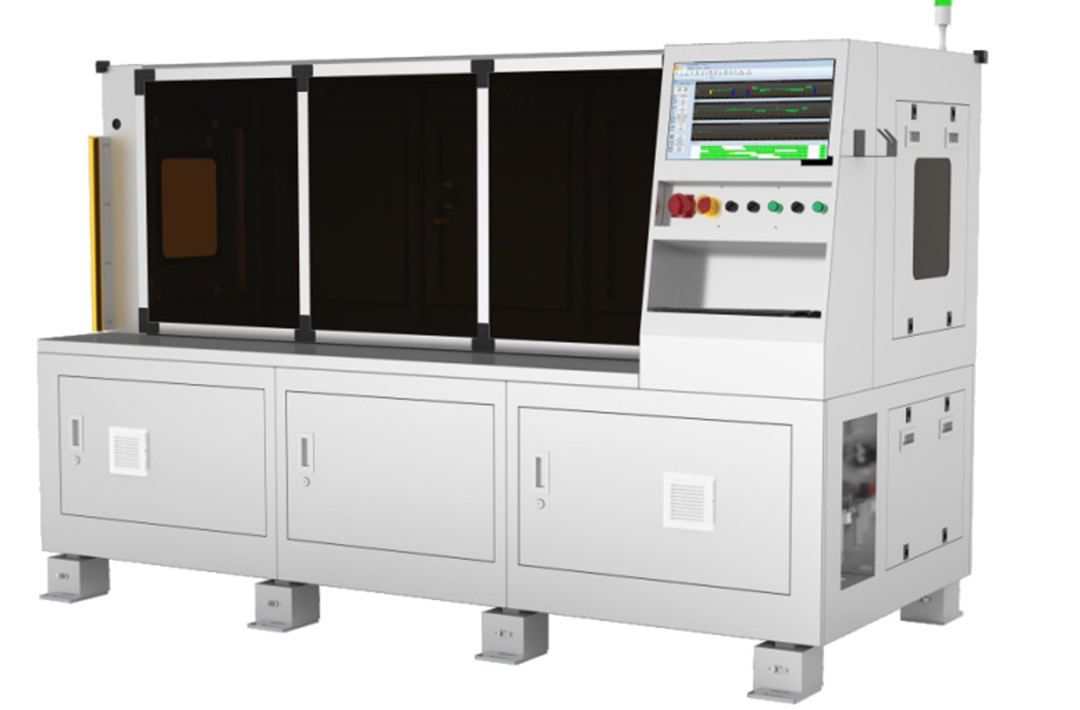

Multi-frame synchronized tracking & measuring system

EtherCAT bus layout

Independent R&D technology: industrial control host + motion controller (EtherNet + EtherCAT)

Synchronization accuracy

Synchronization accuracy: synchronization error ≤ 2mm ( connected to coater encoder );

Specialized motion controller and high-precision encoder are equipped, to ensure the accuracy of synchronous tracking.

Multi-frame tracking diagram

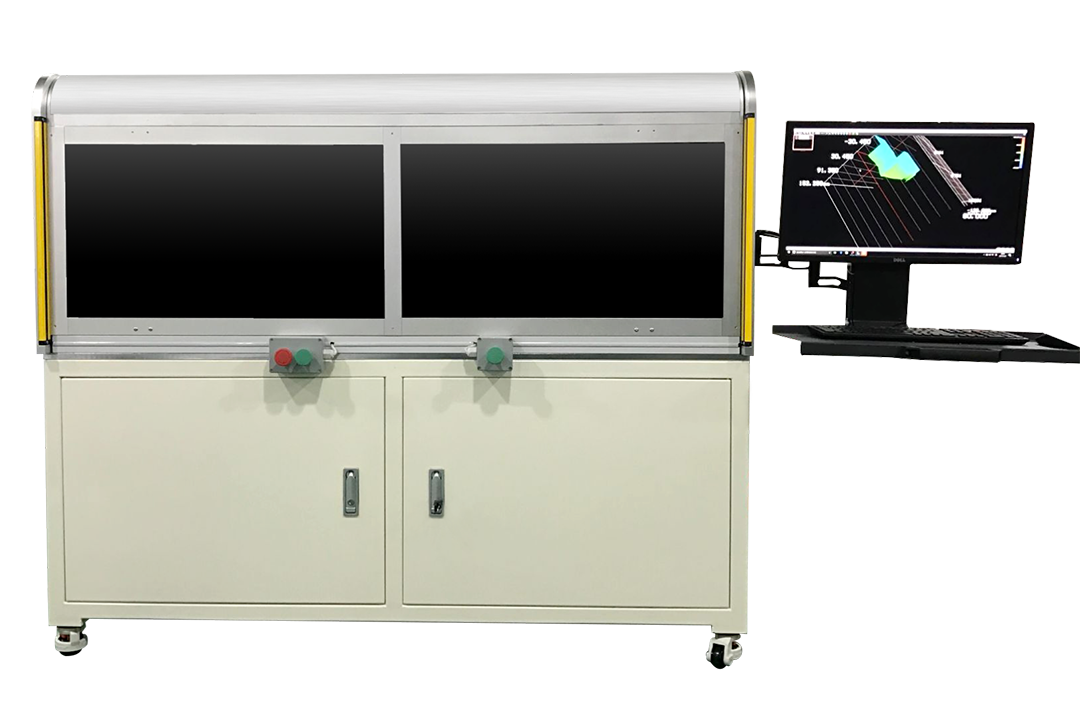

Control software

Information-rich interfaces; customer can choose interfaces for 1#, 2# and 3# frames optionally;

Available for CPK, Max and Min statistics etc.

Measurement of net coating quantity

Measurement of net coating quantity: consistency of net coating quantity is the core index for electrode quality in the coating process;

In the process of production, total weight of copper foil and electrode changes simultaneously and the net coating quantity is basically stable through difference measurement of two frames. Effective monitoring of net coating quantity is of great significance to lithium battery electrode. Background of data collection in the figure below: anode single-side coating a roll of 2,000 meters is produced, he first set of surface density measuring instrument is used to measure the difference of copper foil before coating; while the second set is used to measure the total weight of electrode after coating.