Vacuum baking tunnel furnace series

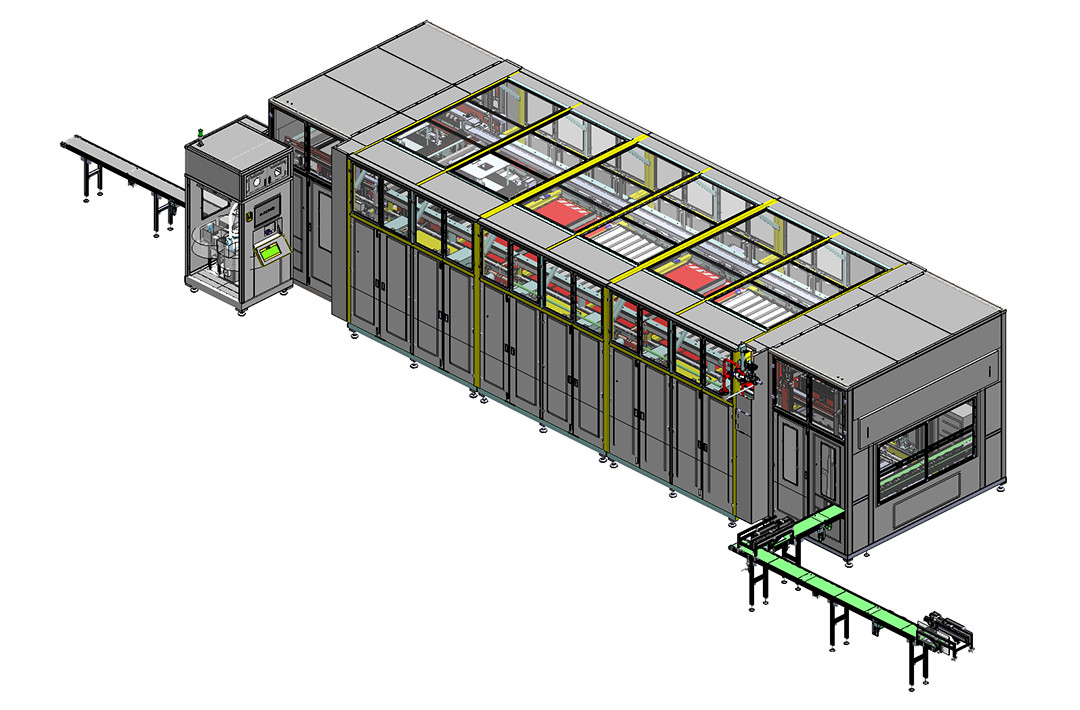

Process flow chart

Equipment characteristics

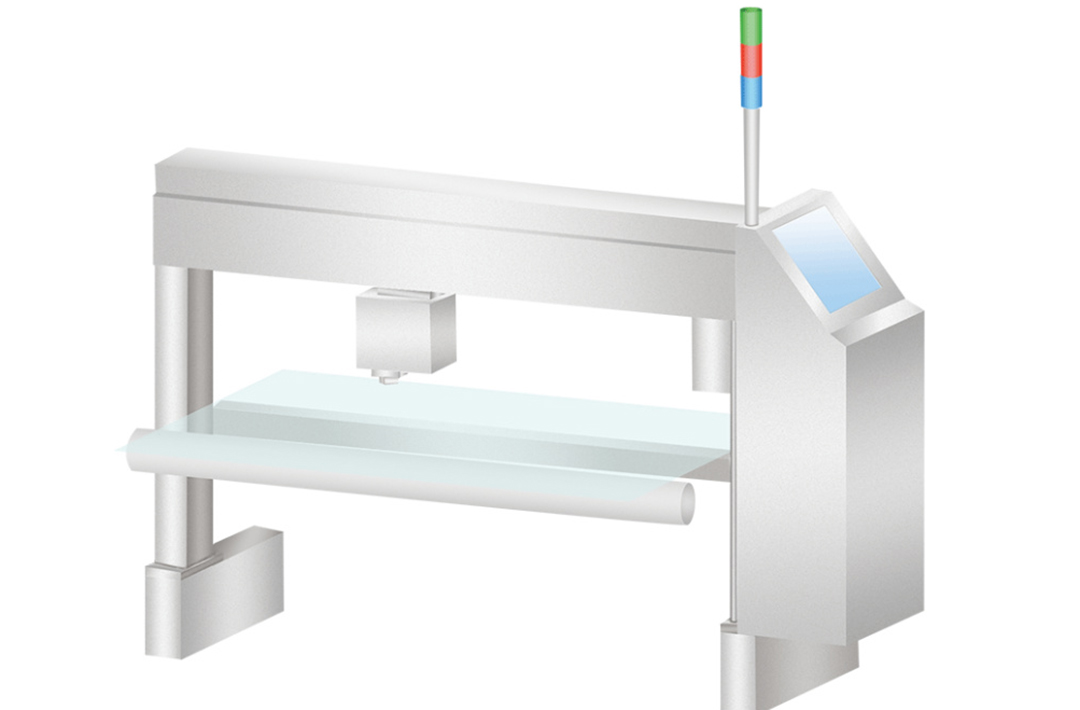

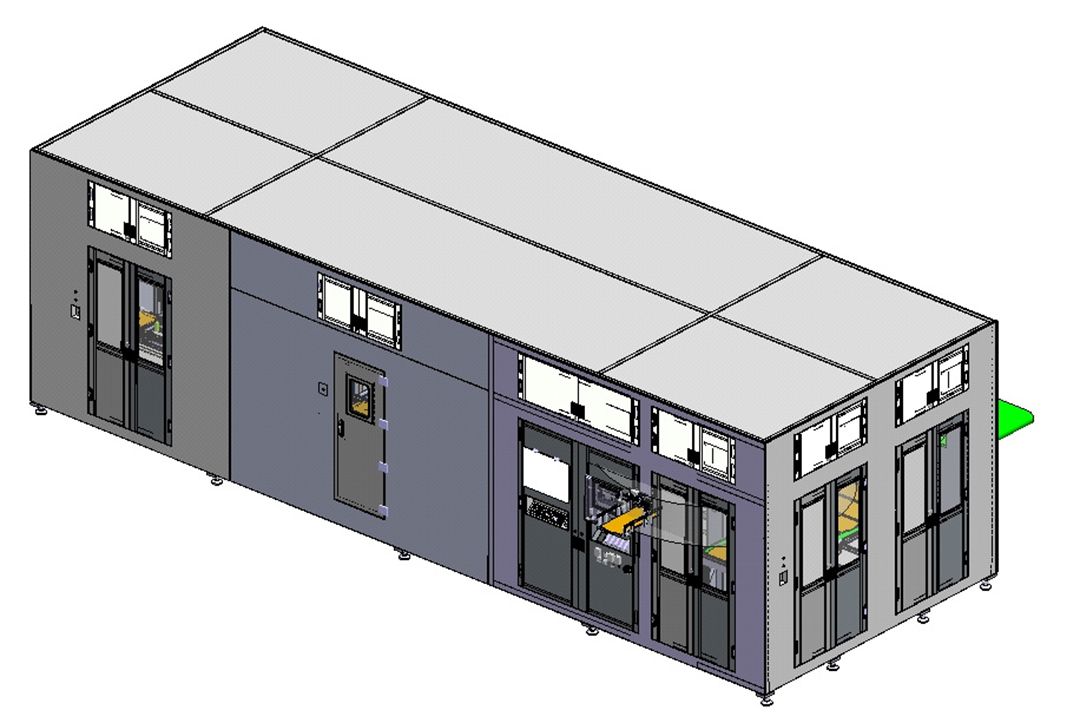

Tunnel chamber layout, clear logic flow, compact structure and small floor space;

Numerous layers of hot plate, high cell capacity for single fixture trolley;

Temperature controller and power switch of the heating plate are placed in the small electric box, with few contacts and it can improve the equipment operation stability;

Small electric box is fed with atmospheric pressure cooling air; temperature controller of hot plate is under atmospheric temperature and pressure and stability of electric control can be assured;

Every layer of hot plate for fixture trolley has separate heating control and it can assure the temperature of hot plate±3℃;

Operate in a closed environment, no drying room is required, It can save the consumption of dry gas.

Equipment application (small pouch/ small steel shell)

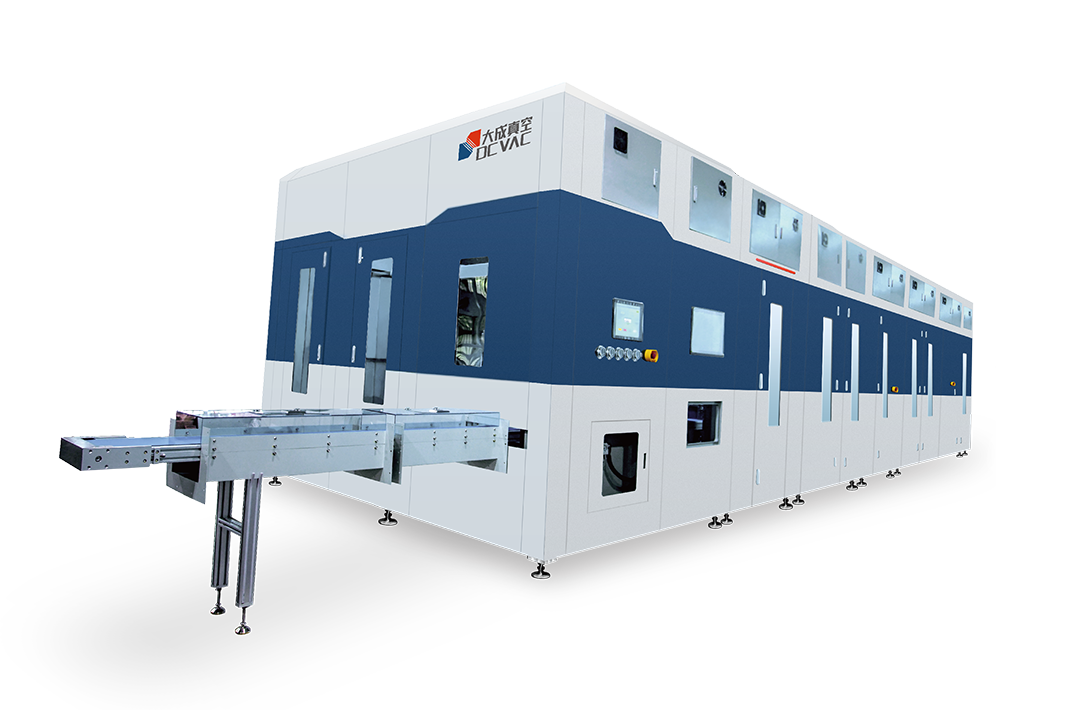

Vacuum drying tunnel furnace

Whole machine is sealed. It only needs to feed dry air in the unloading and discharge areas, so as to ensure dew point and save the energy consumption of dry air, This equipment covers a small area, and its feeding & discharge tapes are connected to the front and rear end equipment conveniently.

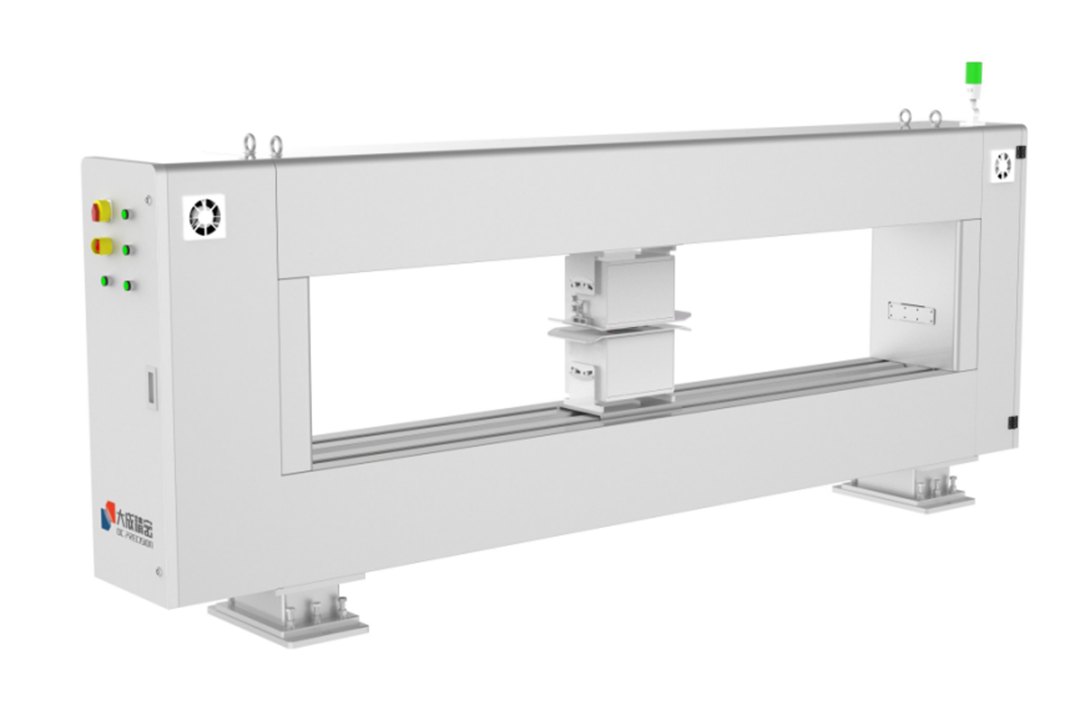

Fixture trolley

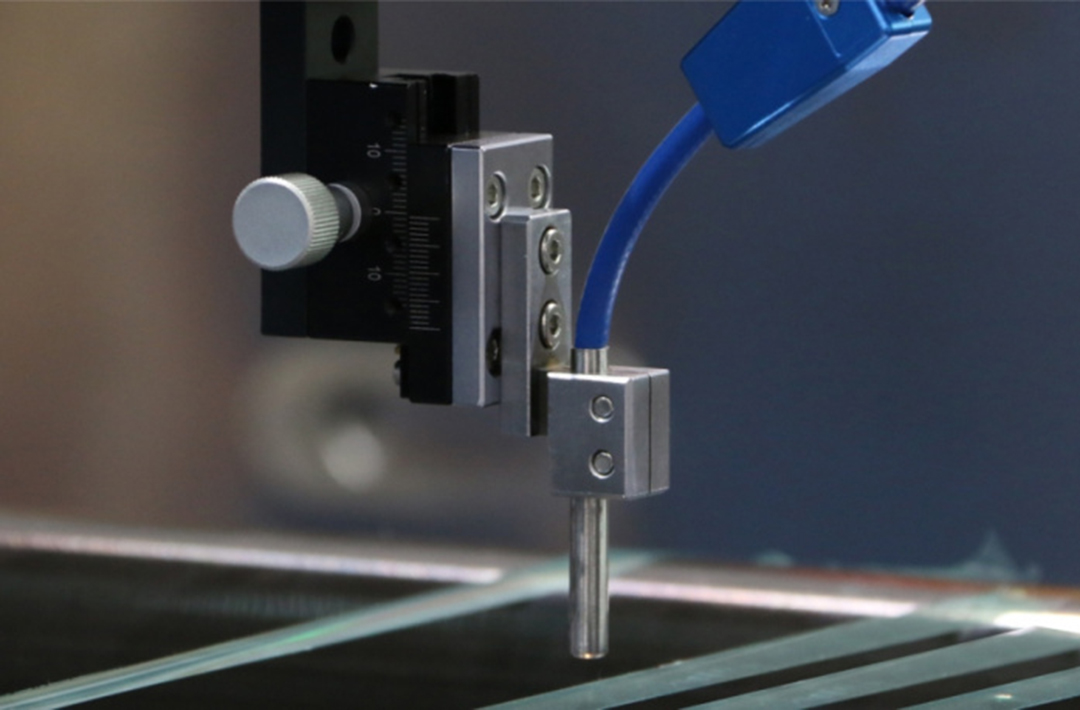

Heating plate

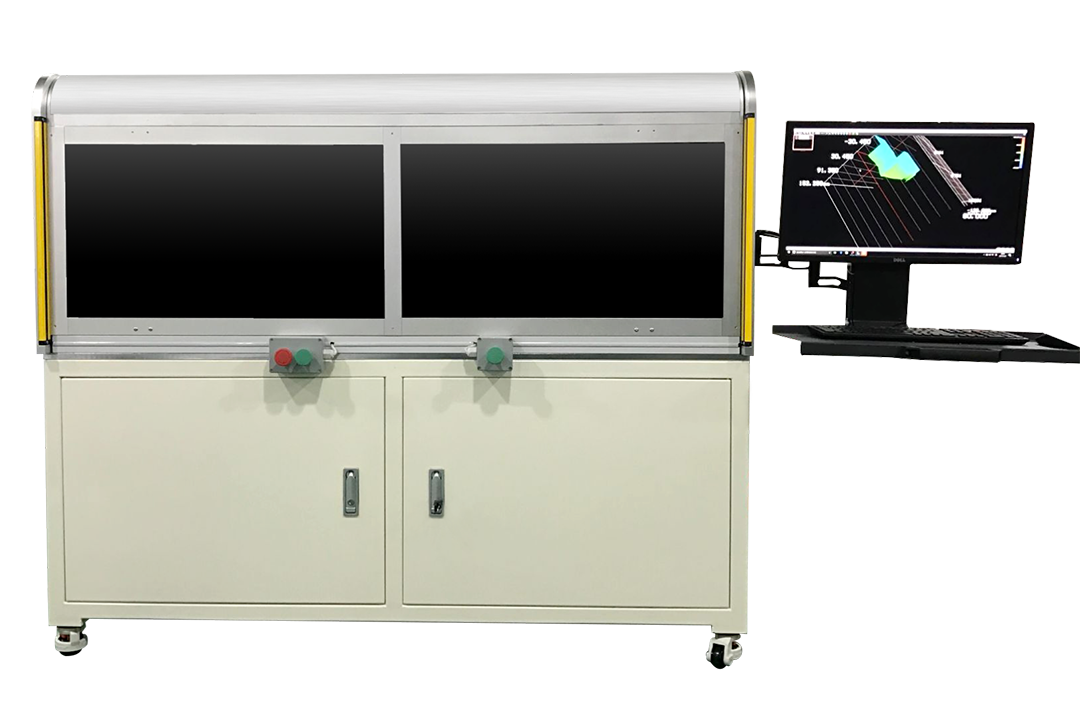

Technical parameters

Equipment dimension: W=11500mm;D=3200mm;H=2700mm

Compatible battery size: L=30~220mm; H=30~220mm; T=2~17mm;

Moisture content: < 100 PPM

Process time: 85~180min

Equipment efficiency: 22PPM

Vehicle battery capacity :300~1000PCS

Allowable number of vacuum chambers: 5~20PCS