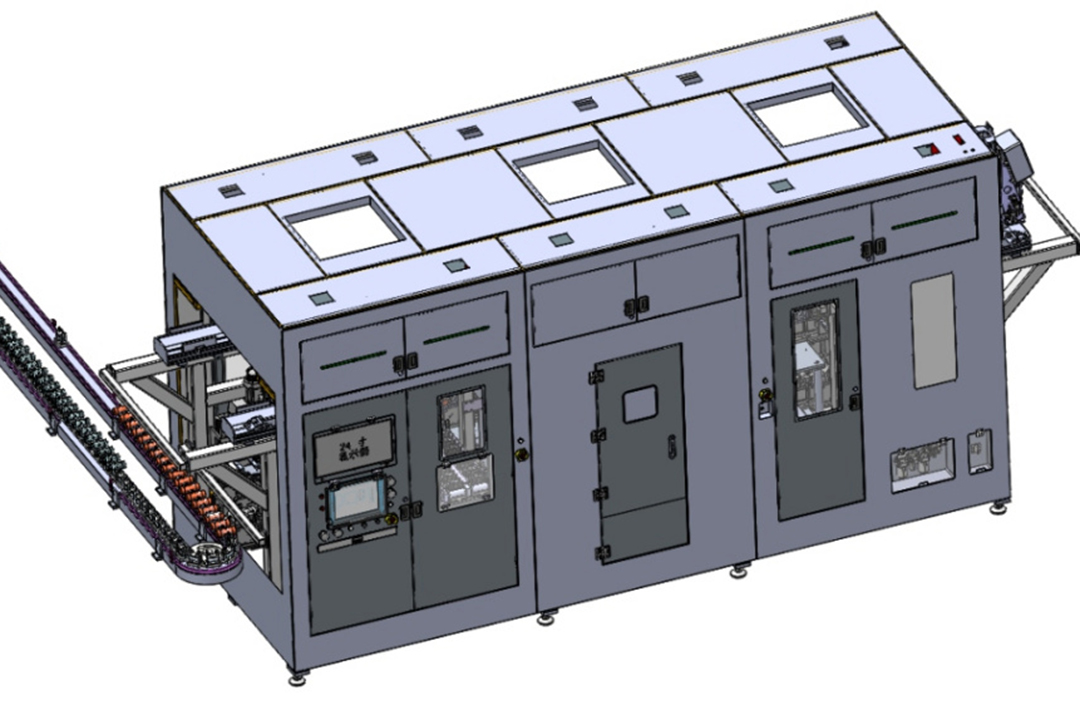

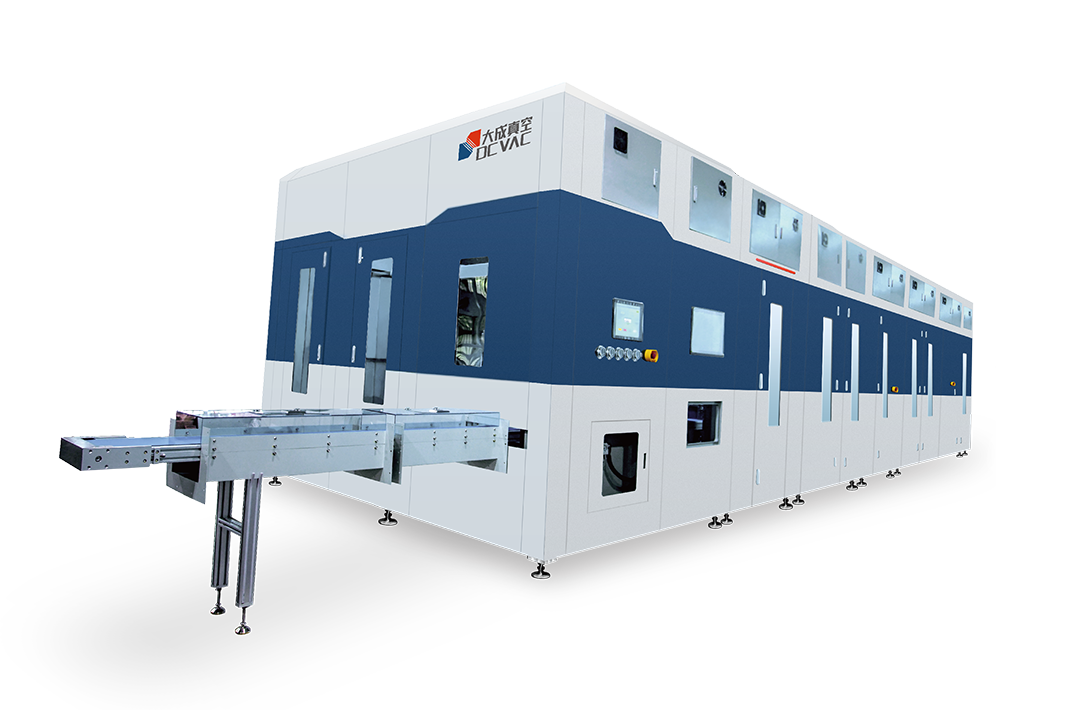

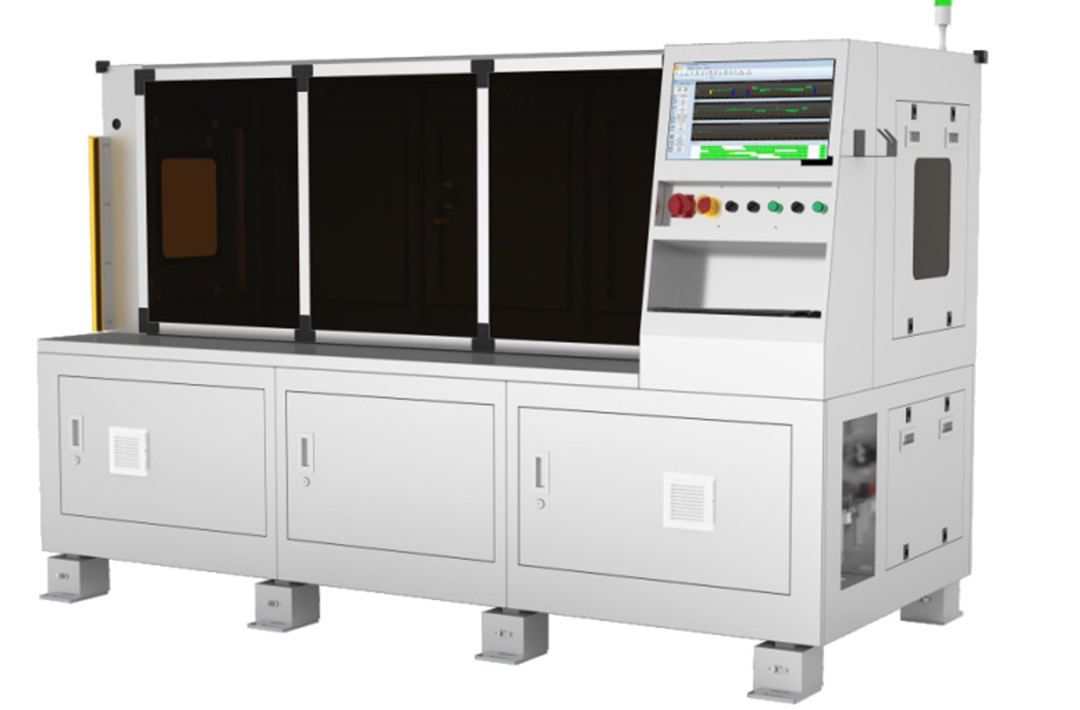

X-ray online cylindrical battery tester

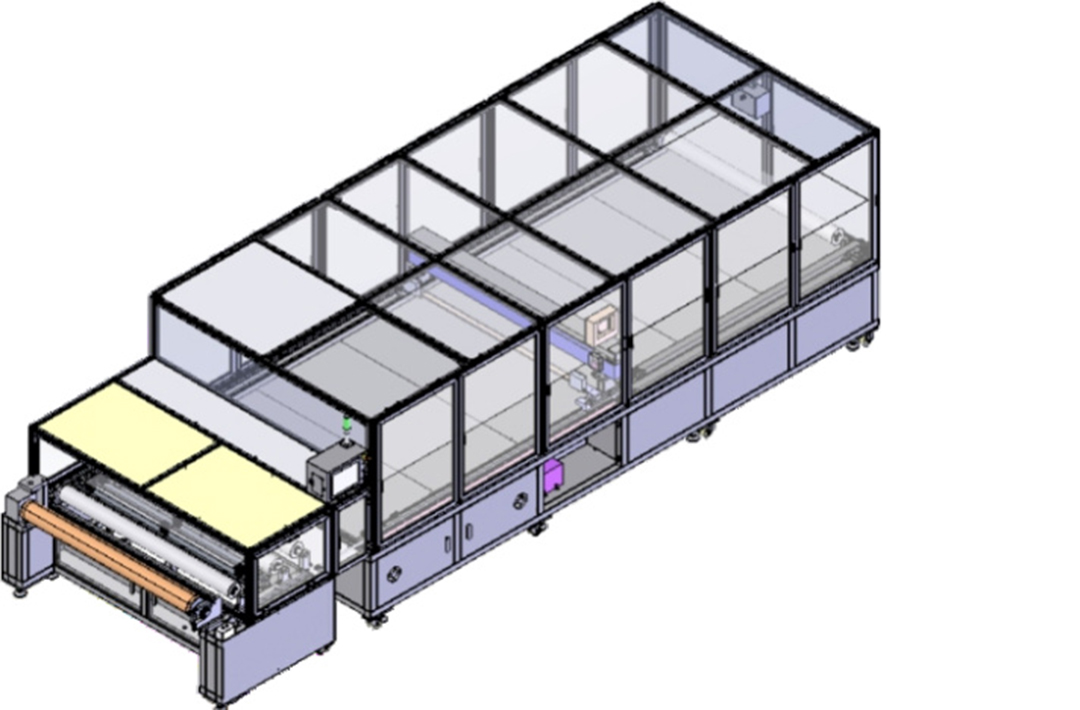

Equipment characteristics

Super large stage and desk detection area

Authority management and intelligent database management

Induction tray, to prevent wrong labeling

Intelligent anti-interference counting algorithm

Support customized connection of MES/ ERP system

Imaging effect

Technical Parameters

| Name | Indexes |

| Takt | 120PPM/set |

| Yield rate | ≥99.5% |

| DT (equipment failure rate) | ≤2% |

| Overkill rate | ≤1% |

| Under-kill rate | 0% |

| MTBF (mean time betweenfailures) | ≥480min |

| X-ray tube | MAX voltage = 150 KV, MAX current = 200 uA; |

| Product dimension | Diameter ≤ 80 mm; |

| Adjustable range of SOD and detector | Flat panel detector is 150~350 mm from the upper surface of cell (battery is placed vertically, ray source and flat panel detector are at both sides of the battery); and the raysource outlet is 20~320 mm from cell surface (customized as required). |

| Photographing time design | Camera shooting time ≥ 1s ; |

| Equipment functions | 1.Automatic code scanning, data uploading and MES interaction; 2.Automatic feeding, NG sorting and blanking of cells; 3.Specified dimension inspection; 4.FFU is configured and 2% dry gas interface is reserved above FFU |

| Radiation leakage | ≤1.0μSv/hr |

| Changeover time | Changeover time for existing products ≤ 2 hours/ person/ set (including commissioning time);Changeover time for new products ≤ 6 hours/ person/ set (including commissioningtime). |

| Feeding mode | Customized as required; |

| Height of testing tape | 950 mm (cell bottom above ground surface) |

Write your message here and send it to us