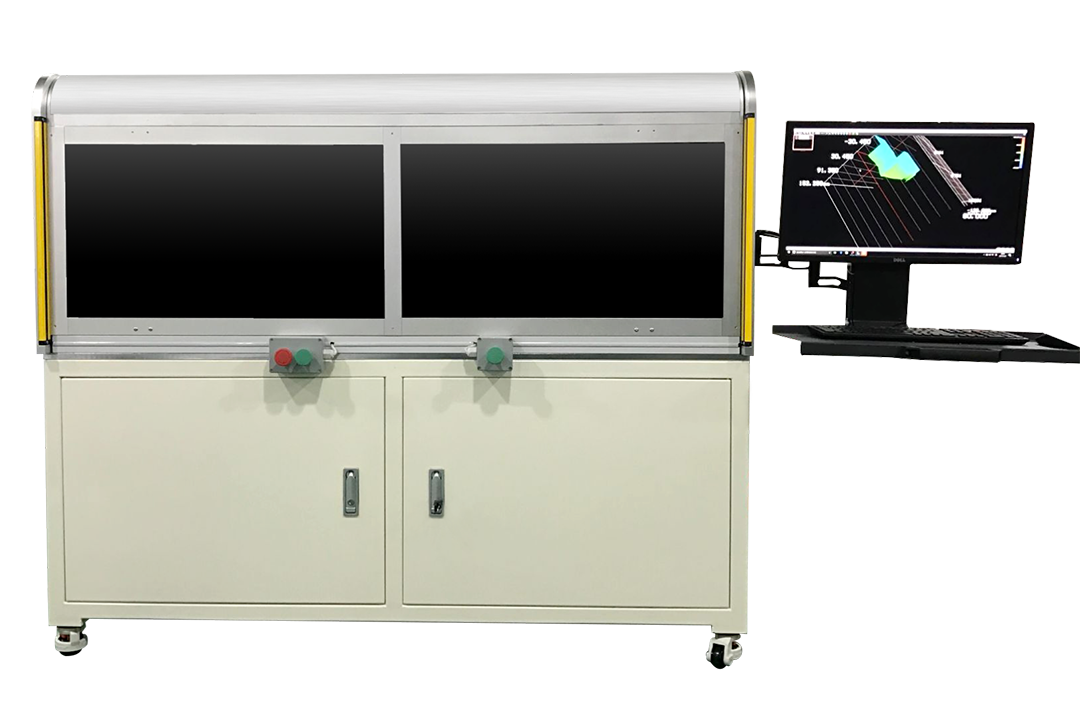

X-ray online laminated battery tester

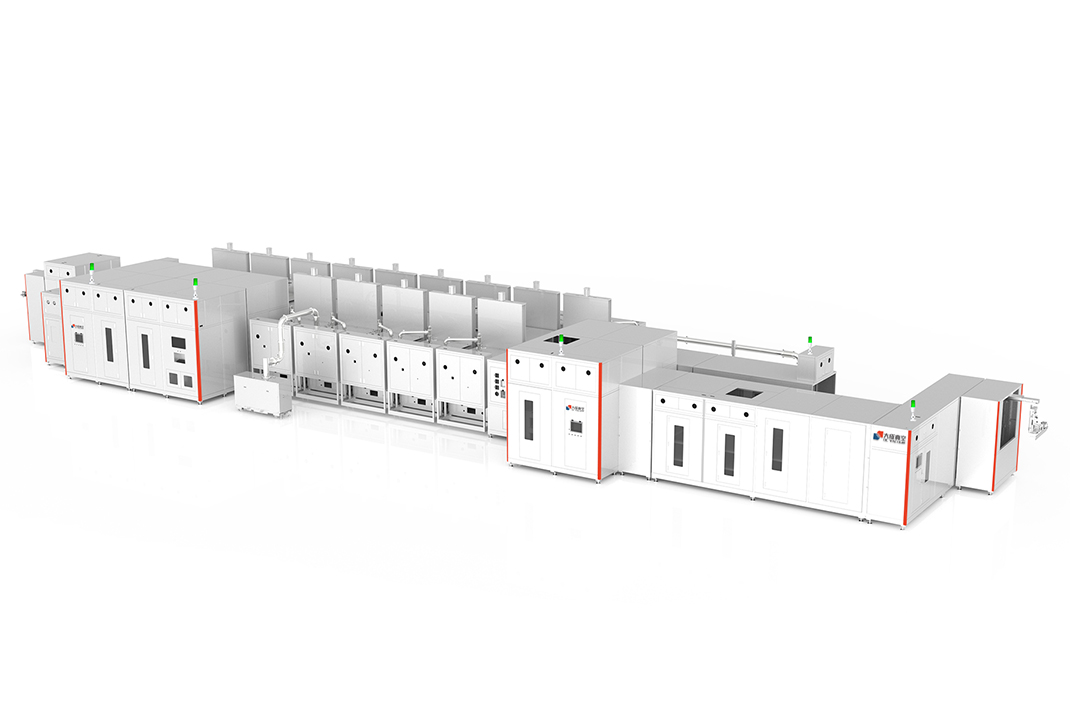

Equipment characteristics

Automatic loading: stop and give an alarm if the incoming direction is wrong;

Automatic code reading: it can identify QR code of pole core and save the data;

Transfer pole core to detection station, mark out the position properly, with the positioning accuracy ±0.1 mm (in the process of positioning, strictly prevent direct contact with pole core side and protect it against damage during positioning);

X-ray emission/ detection: check whether it reaches the required angle; check whether all required angles have been detected, and whether images and data have been recorded and stored.

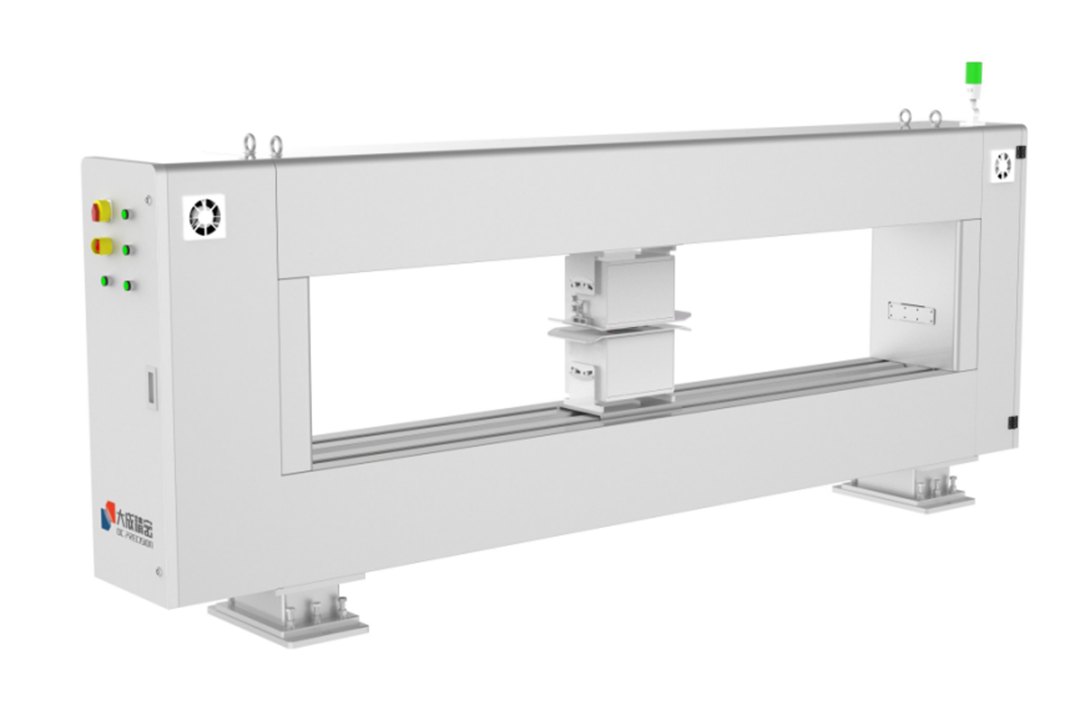

Detection process

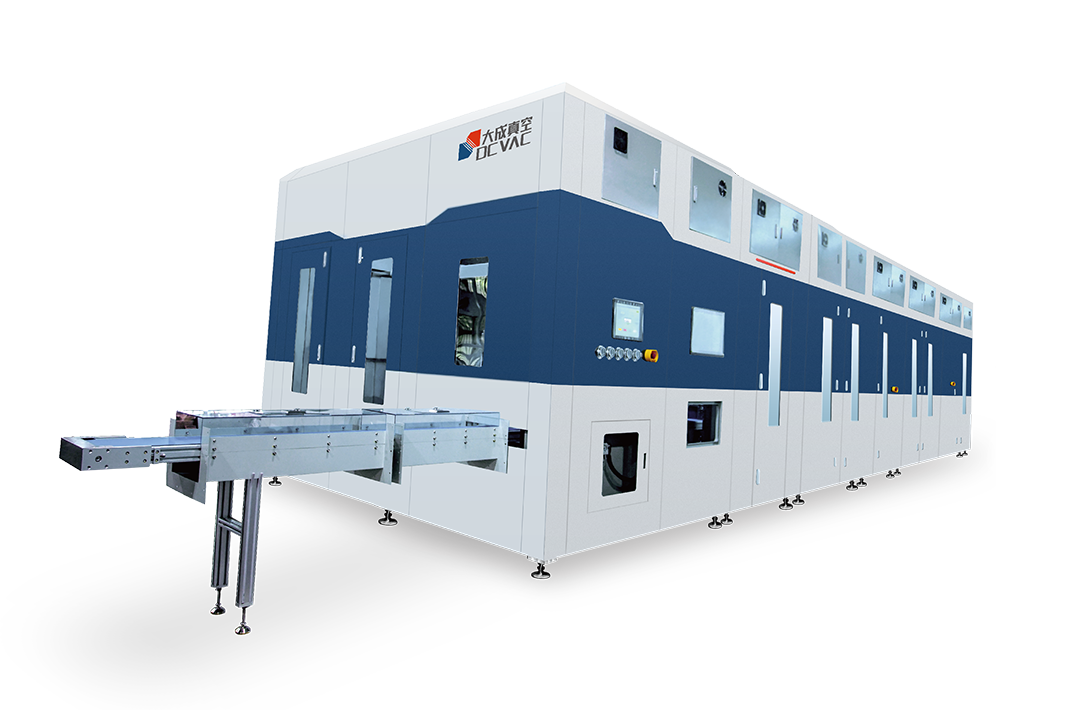

Imaging effect

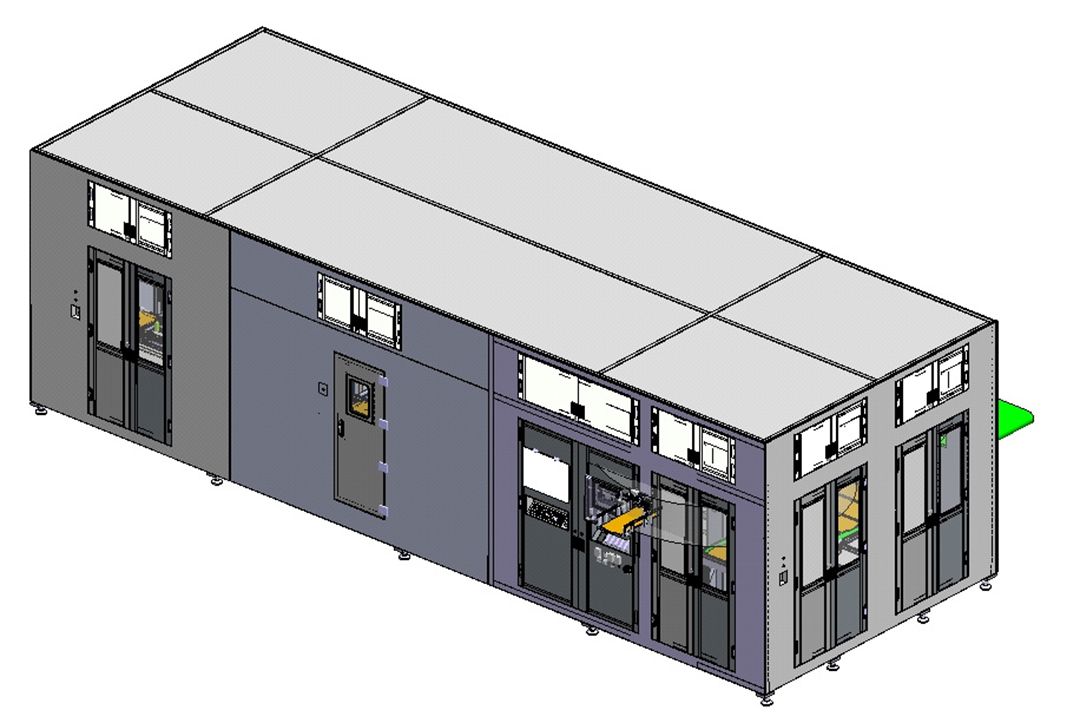

Technical Parameters

| Name | Indexes |

| Equipment dimension | L=8800mm W=3200mm H=2700mm |

| Capacity | ≥12PPM/set |

| Product dimension | Tab: T=10~25mm W=50~250mm L=200~660mm; Tab:L=15~40mm W=15~50mm |

| Feeding mode | Conveyor belt will move cells to the taking position one by one |

| Overkill rate | ≤5% |

| Under-kill rate | 0% |

| X-ray tube | 130KV light tube(Hamamatsu) |

| Quantity of X-ray tubes | 1PCS |

| Warranty time of X-ray tubes | 8000H |

| X-ray detector | TDI linear array camera |

| Quantity of X-ray detectors | 2PCS |

| Warranty time of X-ray detectors | 8000H |

| Equipment functions | 1.Automatic feeding, NG sorting and blanking of cells, 2.Automatic code scanning, data uploading and MES interaction; 3.Detection of four corners of cell; |

| Radiation leakage | ≤1.0μSv/hr |

Write your message here and send it to us