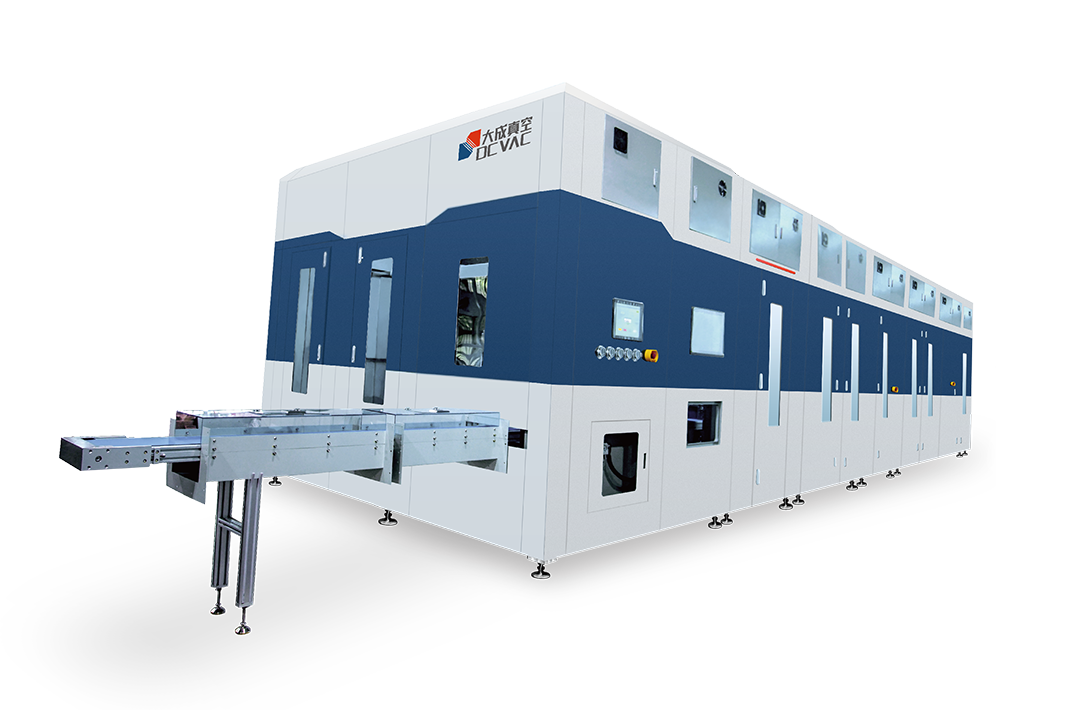

X-ray online winding battery tester

Equipment characteristics

Fully automatic detection: automatic online detection; it can judge and sort out non-conforming products automatically.

Real-time monitoring: achieve real-time monitoring of all actions, signals and hardware status, and facilitate production progress control and quality data analysis.

Image and data storage: save detection and original images simultaneously; and save detection data automatically, to facilitate reference and analysis.

Safety protection: safety interlock of the entire equipment; all parts of the body surface can meet the safety radiation standard of European and American countries.

Convenient operation: authority management function. humanized software interface. easy to use: it can improve the operation efficiency.

Function module display

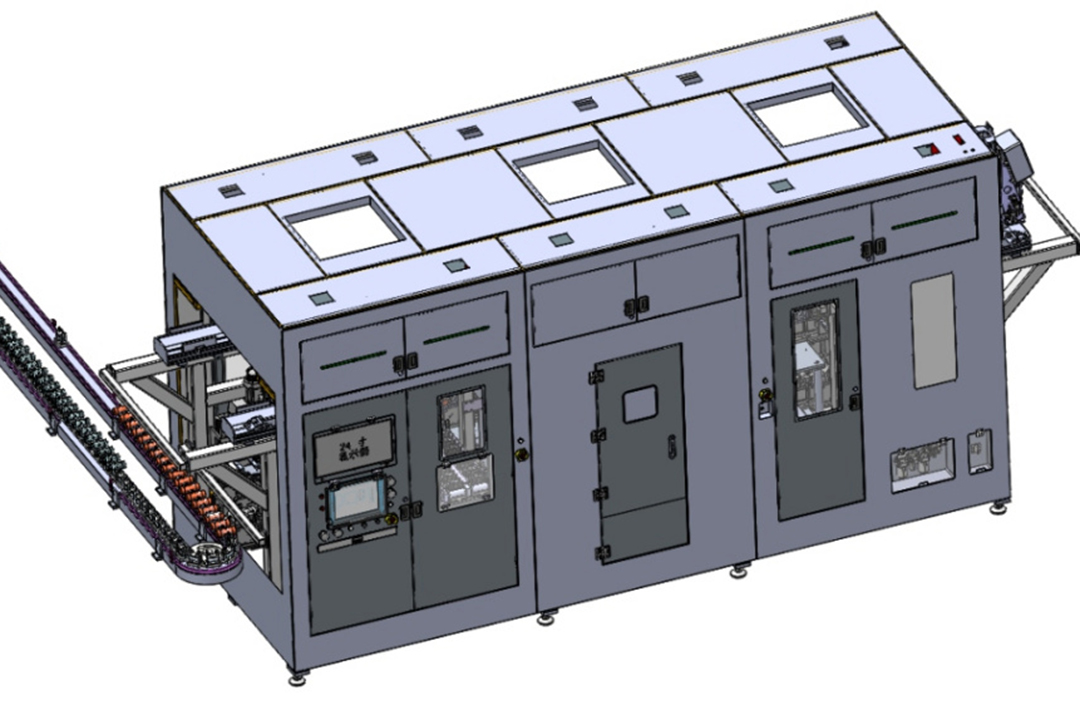

Loading and unloading device

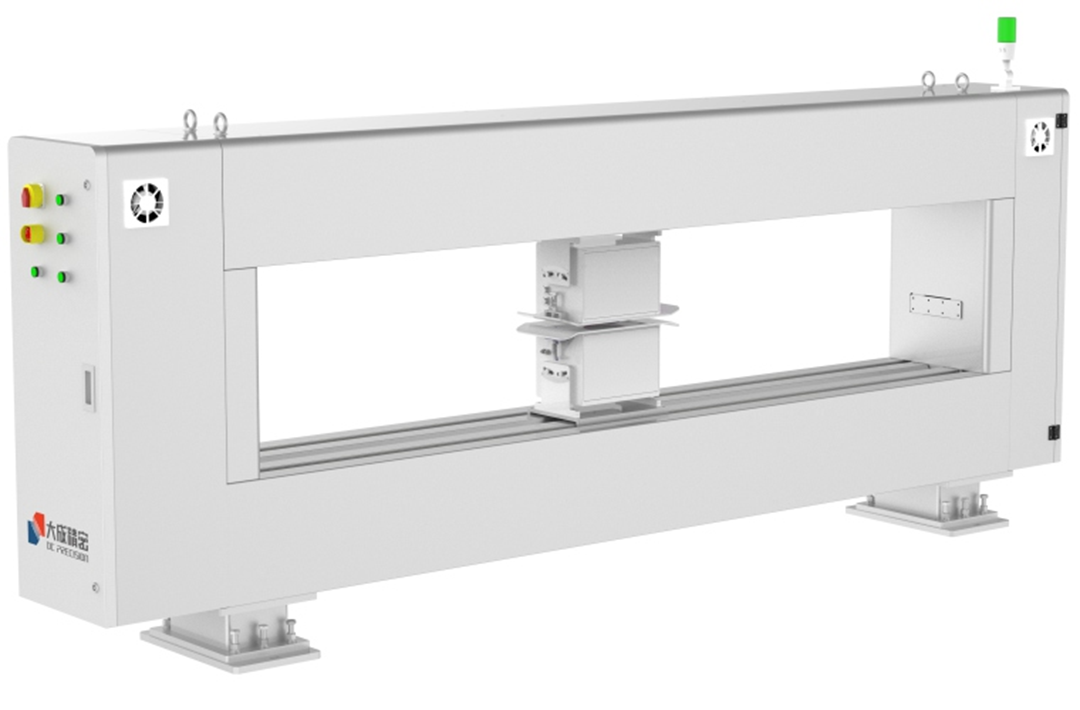

Buffer tape

Detection station

Flow module

Imaging effect

| Name | Indexes |

| Body size | L=7800mm W=2600mm H=2700mm |

| Takt | ≥24PPM/set |

| Yield rate | ≥99.5% |

| DT (equipment failure rate) | ≤2% |

| Overkill rate | ≤1% |

| Under-kill rate | 0% |

| MTBF (mean time between failures) | ≥480min |

| X-ray tube | Voltage MAX=150KV,Current MAX=500uA |

| Product dimension | Compatible with 4JR, JR size: T = 10~40 mm, L = 120~250 mm, H = 60~230 mm, tab height ≤ 40 mm; |

| Test thickness | Detect wrinkle on large surface; detect 4 corners, cathode + anode ≤ 95 layers |

| Adjustable range of SOD anddetector | 1.OH detection; flat panel detector is 150~350 mm from the upper surface of cell(ray source is above the flat panel detector); ray source outlet is 20~320 mm from cell surface. 2、Wrinkle detection; flat panel detector is 50~150 mm from the upper surface of cell(ray source is below the flat panel detector); ray source outlet is 150~350 mm from cell surface. |

| Photographing time design | Camera shooting time ≥ 0.8s : |

| Equipment functions | 1.Automatic code scanning, data uploading and MES interaction; 2.Automatic feeding, NG sorting & blanking, automatic matching of cells; 3.Misplacement detection of four corners of cell and detection of wrinkle on largesurface; 4.FFU is configured and 2% dry gas interface is reserved above FFU. |

| Radiation leakage | ≤1.0μSv/hr |

| Changeover time | Changeover time for existing products ≤ 2 hours/ person/ set (includingcommissioning time); changeover time for new products ≤ 6 hours/ person/ set(including commissioning time) |

| Feeding mode | Feed via two logistics line,1 cell per tray; |